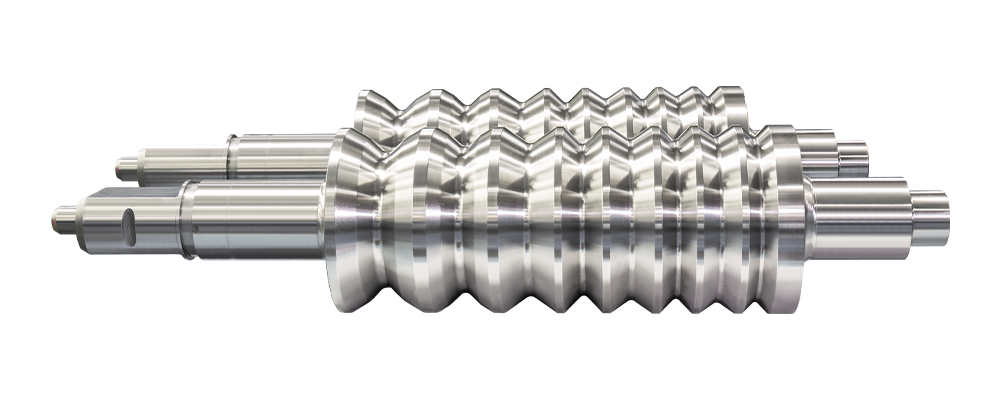

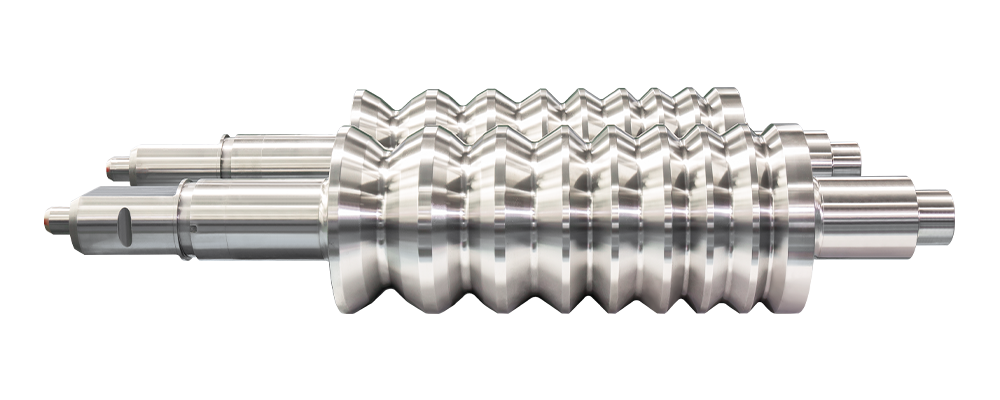

Mediam mittebant Roll Annulum Est discrimine components in gravibus industriae machinatione, offering superior diuturnitatem et perficientur in postulat applications. Hoc comprehensive rector explorat omnia vos postulo scio de his essential industriae components, de vestibulum processus ad sustentationem optimus exercitia.

Quid est missus ferro volumine anulum?

A mastemur ferro volumine circulus est circularis metallum component fabricari per specialioribus mittentes processibus. Hos annulos servire ut gerunt, repugnans superficiebus in volubilem mola, metalla apparatu et alia gravibus machina ubi extrema pressura et frictio sunt assidue challenges.

Dissimilis pyred alternatives, mittite ferro volvunt annulos offer distincta commoda in complexu geometries et customized compositiones. In microstructure potest esse pressius imperium per vestibulum ad consequi specifica mechanica proprietatibus tailored ad diversas industriae applications.

Vestibulum processus summus qualis volumine annulos

Productio Premium cast Mors Roll Annulorum involves pluribus discrimine gradus:

I. Material Electio et Alloy Design

Manufacturers diligenter lego Alloy compositiones secundum intendatur application. Commune offering elementa includit:

- Chromium (nam duritia et gerunt resistentia)

- Nickel (quia lenta et impulsum resistentia)

- Molybdenum (nam summus temperatus viribus)

- Vanadium (quia Frumenti Refinement)

II. Precision Profecto techniques

Moderni Foundries utor proficiebat casting modi ut dimensional accurate et structural integritas:

- Static pro vexillum volumine annulos

- Centrifugal mittentem ad amplificata density

- Continua et pro specialioribus applications

III. Calor curatio processibus

Propriis calor curatio est crucial ad consequi bene mechanica proprietatibus. Typical treatments includit:

| Calor | Temperature range | Beneficia | Communis |

| Normalizing | 850-950 ° C | Frumentum structure | General ad Roll Annulorum |

| Extemprectus | 900-1000 ° C | Maximizes duritia | Summus gere applications |

| Temperans | 300-600 ° C | Reduces fragtilitatem | Impact, repugnant annulos |

| Accentus reliing | 550-650 ° C | Prohibeant distortione | Magna diameter annulos |

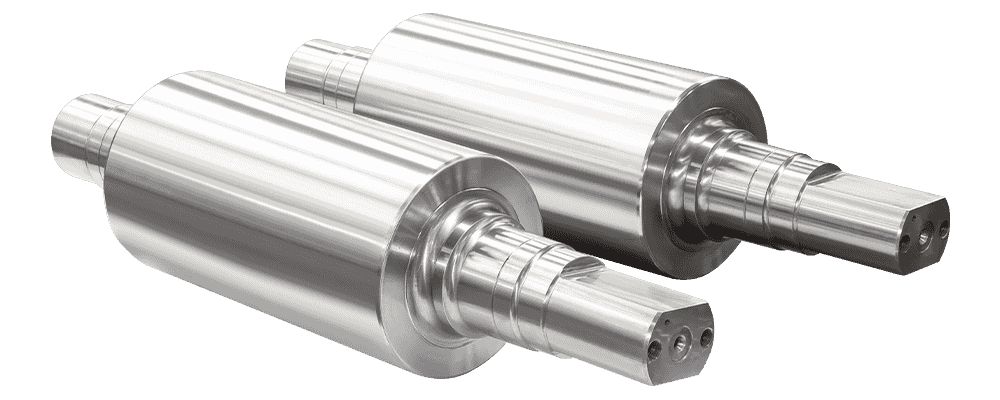

Key proprietatibus premium cast ferro volumine annulos

High-perficientur mittent ferro volumine annulos exhibent plures discrimine characteres qui faciunt ea necessaria in Industrial Occasus:

Exception of Gesss resistentia

In diligenter dispensata microstructure microrum malleam praebet superior resistentia ad abrasive gerunt, significantly extendendo servitium vitae comparari conventional materiae.

Summus temperatus stabilitatem

Special Alloy formulae ponere mechanica proprietatibus usque ad elevatum temperaturis offendit in calidum volubilem applications.

Impact Roughness

Recte calor, tractata mittebant volumine annulos potest resistere significant impulsum onerat sine fregisset vel deformatio.

Customizable duritia profiles

Per differentiam calor curatio, manufacturers potest creare volumine annulos cum vario per crucem-sectionem ad optimize perficientur.

Industrial applications de cast ferro volumine annulos

Haec versatile components Servite discrimine munera trans Tullius Industries:

Steel volubilem Mills

Mediam mittebant volumine circulos sunt essential:

- Calidum habena mola

- Laminam mola

- Sectionem mola

- Status virga molendinas

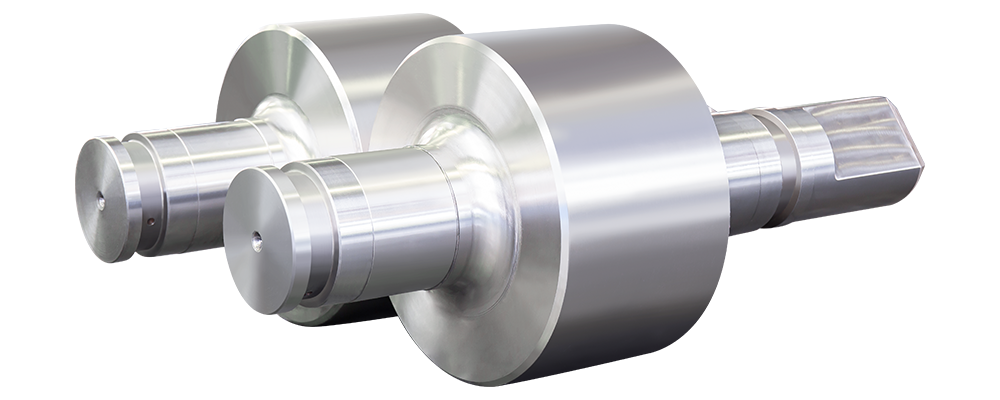

Mining et mineralis processus

Gravis-officium applications includit:

- Crusher rotulis

- Molendini annulos molere

- Material Tractantem Equipment

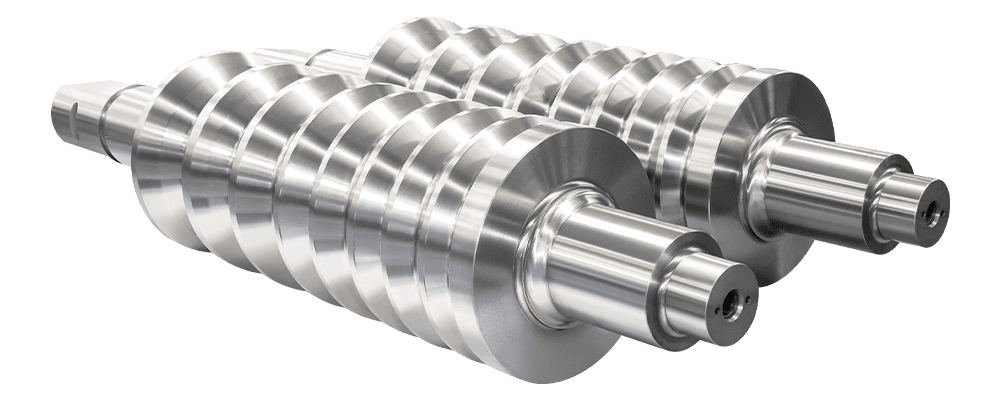

Charta vestibulum

Specialized cast ferro annulos in:

- Torcular rotulis

- Calendar rotulis

- Yankee dryer conchas

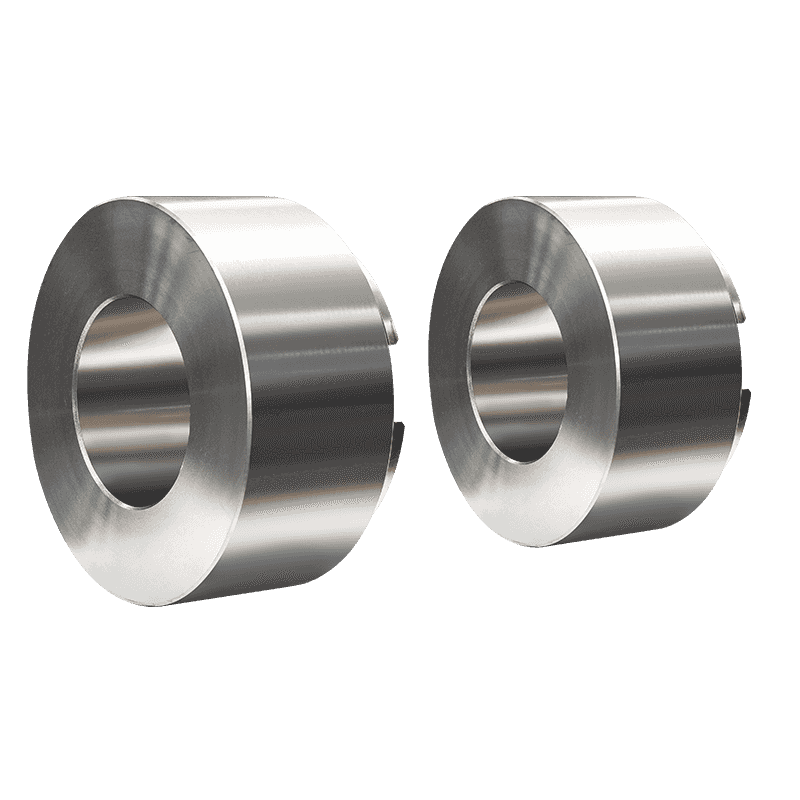

Delectos ius cast Mors Roll Annuli

Eligens optimal volvunt circulum requirit diligenter consideratione pluribus factoribus

Operating conditionibus

Evaluate:

- Temperature range

- Onus characteres

- Contact Pressures

- Environmental factores

Materia

Key parametri includit:

- Durness Requirements (Brinell aut Rockwell scale)

- Impact Toughness (Charypy Values)

- Gerunt resistentia indices

Dimensional requisitis

Critica mensura:

- Exterior diameter tolerantia

- Testimonium

- Faciem latitudine

- Runout cubits

Sustentationem et Service Vita Tractus

Propriis sustentationem potest significantly extend in operational vitae castra volumine annulos:

Ordinarius inspectionem protocols

Exercitatione Morbi rhoncus reprehendo peragendam:

- Superficiem Cracks (Using NDT Modi)

- Gerunt patterns

- Mutationes dimensional

Propriis lubricatae exercitia

Use Manufacturer, suadetur:

- Lubricant types

- Applicationem frequentiis

- Delivery modi

Refurbishment options

Commune refurbishment ars includit:

- Hardfacing

- Machining ad restituere profiles

- Thermal RESPERSIO

Pretium-beneficium Analysis: Meder Ferro Vs Africa Materials

Cum aestimandis volumine circulum optiones considerans haec key comparationes:

Steel Mors Steel vs.

Mediae offert:

- Melius complexionem in figuris

- Magis consistent proprietatibus in magna sectiones

- Infra Tooling costs pro Custom Cogitationes

Mediae Mors vs. Composite Materials

Medius Steel providet:

- Superior summus temperatus perficientur

- Melius impulsum resistentia

- Magis praedictable gerunt exemplaria

Future trends in cast Mors Roll Technology

In industria continues ad evolve cum pluribus emergentes explicationibus:

Provectus Alloy Development

Novum Micro-comminutum compositiones promittere:

- Enhanced gerunt resistentia

- Improved lenta

- Melius corrosio praesidium

Digital vestibulum elit

Incorporation of:

- Simulatio, secundum consilium

- Predictive Sustentacionem algorithms

- Ai-repulsi qualis imperium

Sustainable productio modi

Eco-amica incepta includit:

- REDIVIVUS Material usus

- Energy-efficientem calor curatio

- Reducitur vastum iactu processuum

Frequenter Interrogata Quaestiones

Quid est typical lifespan de cast ferro volumine circulum?

Service Vita Varies significantly secundum applicationem, sed proprie sustinenda mittebant malleo volumine circulos typice ultima inter 6-18 menses in continua operatio ante postulantes refurbishment aut replacement.

Potest mittere ferro volumine annulos reparari?

Ita, plura reparare modi sunt available inter hardfacing, aedificare-sursum welding, et machining. In opportunitate modum pendeat ex parte gerunt et propria applicationem requisita.

Quid ego identify cum volumine anulus necessitates replacement?

Key Indicatores includit nimia tremor, visibilis superficiem rimas ultra gratum fines, dimensional mutationes afficiens productum qualitas, aut gerunt exemplaria, quod non potest corrigi per normalis sustentacionem ratio.

Conclusio

Mediae Roll Rock Repraesentant a Critical Obstringimment pro Industrial Operations requiring Dura, High-perficientur Rolling components. Per intellegendum est vestibulum processus, materiam proprietatibus et propriis sustentacionem technicae outlined in hoc duce, operators potest maximize ad valorem eorum volumine circulum in investments dum minimizing et operational costs.

Sicut technology progreditur, possumus expecto etiam magis sophisticated mittetur ferro solutions ad emerge, porro enhancing ad capabilities et Vivacitas de his essential industrialis components.

中文 简体

中文 简体