Mediae Roll Sunt discrimine components in metallicking industries, praecipue in volubilem mola. Et offerre sumptus-effective solutio optimum gerunt resistentia, lenta et scelerisque stabilitatem. Hoc articulum explorat proprietatibus, vestibulum processus, et clavis applications dejicite ferro rotulis dum comparet eos in alternative volumine genera.

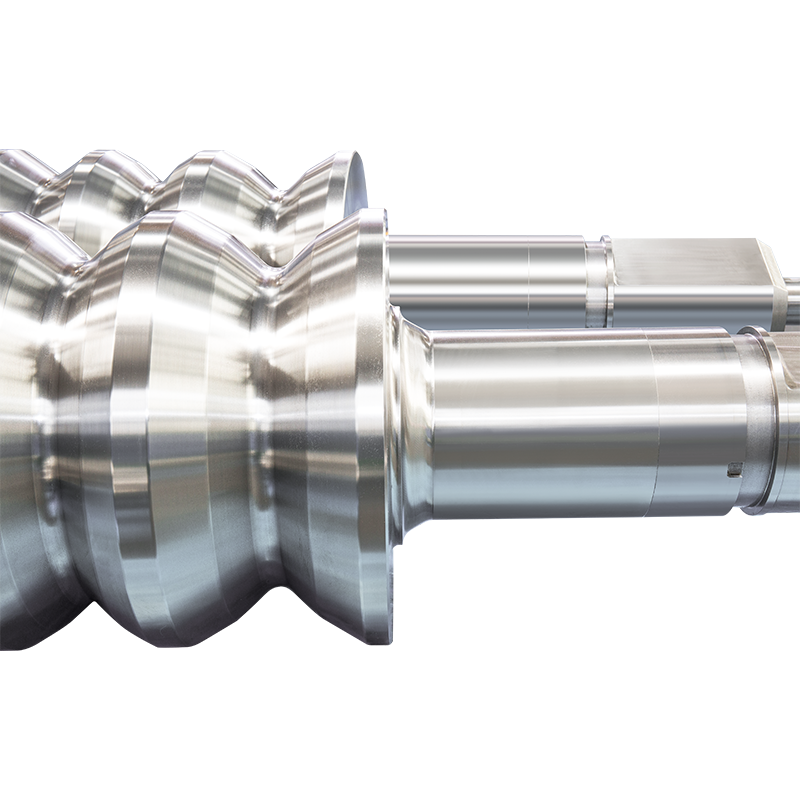

Mediae volumine est a cylindricum tool in volumine mola ad figura, reducere crassitudine, aut impertiet superficiem finiatur metallum products. Hae rotulis producuntur per mittentes modi, offering distincta commoda quaedam industriae applications.

Mediamque volumine possident plures amet quod idoneam petens Industrial Applicatios:

| Res | Descriptio | Momentum |

|---|---|---|

| Durities | Typically 35-85 HS (Durness Shore) | Decernit gerunt resistentia |

| Lentitudo | Maximum impulsum resistentia | Prohibet fregisset sub accentus |

| Scelerisque stabilitatem | Maintains properties ad altum tentat | Essential ad calidum volubilem |

| Gerunt resistentia | Superior multis frumento rotulis | Sequitur ministerium vitae |

Productio summus qualitas mittebant rotulis involves plura praecisa gradibus:

Lignum vel metallum exemplaria creantur ad formare fingunt cavum ad volumine.

Arena formae parata per exemplaria, typice usura resin-bonded harenae ad meliorem superficiem metam.

Steel est liquefactum in electrica arcum Furnaces ad temperaturis circa MDC ° C (MMCDXII ° F) et diligenter infudit in formam.

Et refrigerationem rate est regitur ad consequi desideravit microstructure et minimize internum passiones.

Rolls subeunt processibus sicut extinxit et temperatio ad consequi meliorem mechanica proprietatibus.

Finalis dimensiones et superficiem metam effectum per conversus, molere, et politura.

Ultrasonic temptationis, duritia mensuras, et dimensional checks ensure uber qualitas.

Mediam mittebant rotulis serve in variis industriae sectores:

| Industria | Application | Roll Type |

|---|---|---|

| Ferro productio | Calidum volubilem mola | Tergum rotulis, opus rotulis |

| Non-ferrea metalla | Aluminium Rolling | Medium rotulorum |

| PROPRESSUS | PRAEMULATIO | Magna diametro rotulis |

| FILIUS productio | Virga mills | Struo rotulis |

Comparari aliis volvunt types, mittebant rotulis offer multa beneficia:

Inferioribus productio costs comparari cogebantur rotulis, praesertim magna diametrorum.

Complexa internum refrigerationem canales potest incorporatus in casting.

Alloy compositionem potest esse pressius ad propria applications.

Potest produci in magnitudinum difficile ad consequi per coelum.

Intelligendo Differentiarum adjuvat in eligendo ius volumine type:

| Parameter | Mediam mittebant rotulis | Cogitavit chalybe rotulis |

|---|---|---|

| Productio modum | Iactus | Fuscus |

| Frumentum | Grana maior | Denique, directional grana |

| Cost | Plerumque inferioribus | Superior |

| Magnitudine limitations | Paucioribus restrictiones | Limited per foris facultatem |

| Optimum | Large Diametris, complexu figuris | Summus accentus applications |

Propriis sustentationem extendit volumine vitae et maintains productum species:

Reprehendo in superficiem rimas gerunt exemplaria et dimensiva mutationes.

Store horizontaliter in Padded quatit in siccis condiciones ne abstulit et rubigo.

Uti oportet elevatio apparatu vitare impulsum damnum.

Effectum deducendi propriis Purgato et lubrication operandi usum.

Remove superficiem defectibus ante se propagare altius rimas.

Intellectus defectum machinationes adjuvat in praeventionis:

| Defectum type | Caussa | Praeventionis modi |

|---|---|---|

| Trucidus | Lassitudine, obruuntur | Propriis duritia lectio |

| Thermal fregisset | Celeri temperatus mutationes | Controlled cooling |

| Wear | Abrasive contactus | Hardfacing or coatings |

| Breakage | Impact, defectus | Imperium |

Innovations continue to improve roll performance:

New compositions offer better combinations of hardness and toughness.

Computer-controlled processes ensure more consistent properties.

Advanced NDT modi deprehendere minor vitiisque priorum.

Laser treatments and coatings extend service life.

Consider these factors when choosing rolls for your application:

| Elementum | Consideratio |

|---|---|

| Rolling | Hot vs. cold rolling requirements |

| Material Being Rolled | Hardness and abrasiveness |

| Production Volume | Altum volumen indiget magis gerunt, repugnans rotulis |

| Mill Configuration | Roll positioning and stresses |

| Budget | Initial cost vs. total lifecycle cost |

Cast steel rolls remain essential components in metal rolling operations, offering a balance of performance and cost-effectiveness. Understanding their properties, manufacturing processes, and proper application helps industries maximize their value. With ongoing technological advancements, cast steel rolls continue to evolve, meeting the ever-increasing demands of modern metal processing.

Service life varies widely (from weeks to years) depending on application conditions, material rolled, and maintenance practices.

Yes, techniques like hardfacing and grinding can extend service life, depending on the damage extent.

Higher carbon generally increases hardness but reduces toughness. Optimal balance depends on specific application needs.

Typically 8-12 weeks for standard sizes, longer for custom or large diameter rolls.

Yes, their longer service life and recyclability contribute to reduced environmental impact compared to frequent replacements.